- Home

- >

News

Low temperature bellows sealing is a sealing technology used in extreme low temperature environments, which ensures the safety of pumped fluids while providing long-term reliability. When designing pumps for transporting low-temperature fluids, special designs are often used, such as vertical multi-stage double shell pumps according to the American Petroleum Institute (API) 610 standard. These pumps have a heating chamber called a cofferdam that can thermally isolate the shaft seal from the cold pumped fluid, allowing for the use of traditional sealing techniques

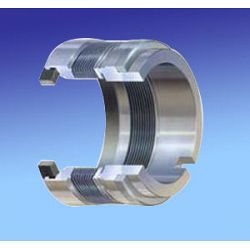

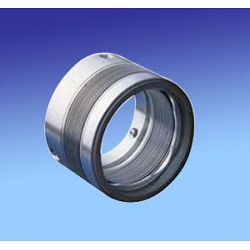

Famious Hanway industries' type HW606 is a high-temperature and corrosion-resistant rotating corrugated pipe component that uses different materials Including heat treated AM350 or Alloy 718 bellows, low expansion alloy sealing surface retainer, and 316 stainless steel wheel hub and housing and Inconel material. They can reliably seal fluids in harsh high-temperature corrosive environments and provide excellent sealing surface stability at high temperatures.