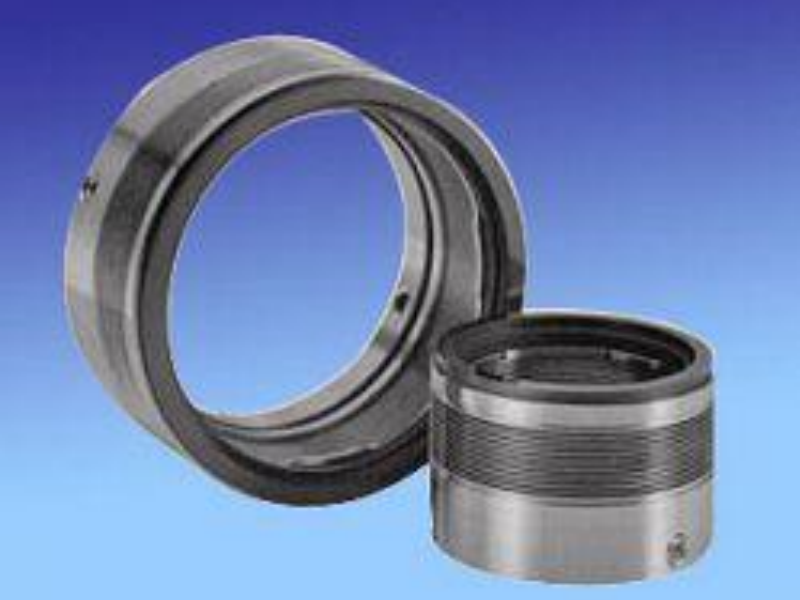

High Temperature Rotating Bellows Seal

1. Our High temperature rotating bellows seal effectively prevents leakage.

2. Our High temperature rotating bellows seal can be customized.

3. Our High temperature rotating bellows seal adopts rotating design.

- Dandong City, Liaoning Province

- 1 month

- 100 units/month

- Information

Introduction to High temperature rotating bellows seal:

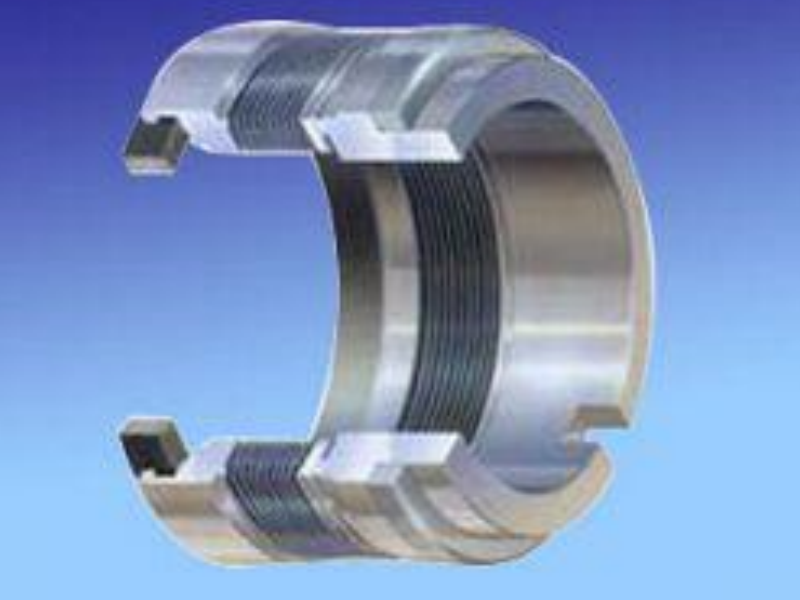

Formed bellows seal's products have unique structural features and high applicability. Formed bellows seal has a wide range of applications, the temperature range is -75 to 425°C, and the pressure range is 2.5MPa under vacuum or 6.9MPa under vacuum (using double-layer bellows). The maximum line speed of welded metal bellows seal is 25m/min. The suitable media include oil, liquid hydrocarbons, acids and bases, solvents, asphalt, etc. Our welded metal bellows seals include HW604, HW606, HW609, and HW80T.

Advantages of High temperature rotating bellows seal:

1. Welded metal bellows seal can maintain excellent sealing performance in high temperature environments.

2. The rotating design of the welded metal bellows seal allows the seal to rotate with the rotation of the shaft, thereby avoiding heat and wear due to friction and wear, and extending the service life of the product.

3. formed bellows seal is suitable for various harsh working conditions and media, such as high temperature, high pressure, corrosiveness, etc.

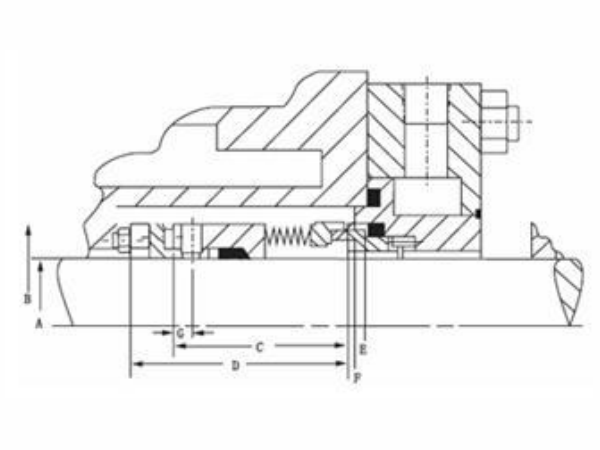

High temperature metal bellows rotary seal HW604 parameters:

High Temperature, Stationary Head Metal Bellows Shaft Seal | |

Temperature: | -75℃~ 425℃ |

Pressure: | 2.0MPa(single ply)-6.9Mpa(double ply) |

Speed: | ≤50m/s |

Equivalent John Crane Type 604 | |

Rotary Ring: | SiC/TC |

Stationary Ring: | SiC/Carbon/TC |

Secondary Seal: | Flexible Graphite |

Metal Bellows: | AM350/Inconel 718 |

Other Parts: | Carp42 or PH17-4/316 |

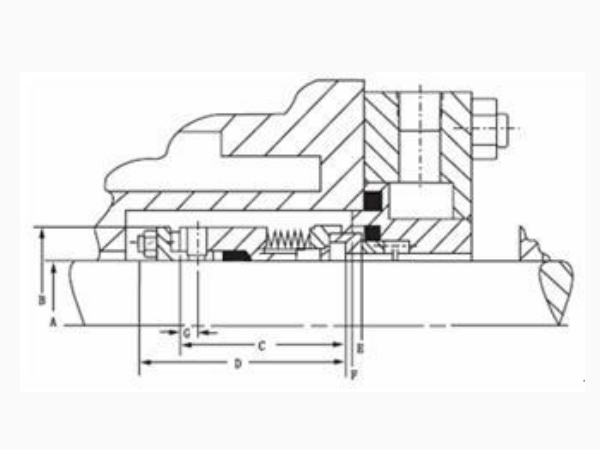

High temperature metal bellows rotary seal HW606 parameters:

High Temperature, Rotating Head Metal Bellows Shaft Seal With Lug Drive | |

Temperature: | -75℃~ 425℃ |

Pressure: | 2.0MPa(single ply)-6.9Mpa(double plys) |

Speed: | ≤25m/s |

Equivalent John Crane Type 606 Rotary Ring: | SiC/Carbon/TC |

Stationary Ring: | SiC/TC |

Secondary Seal: | Flexible Graphite |

Metal Bellows: | AM350/Inconel 718 |

Other Parts: | Carp42 or PH17-4/316 |

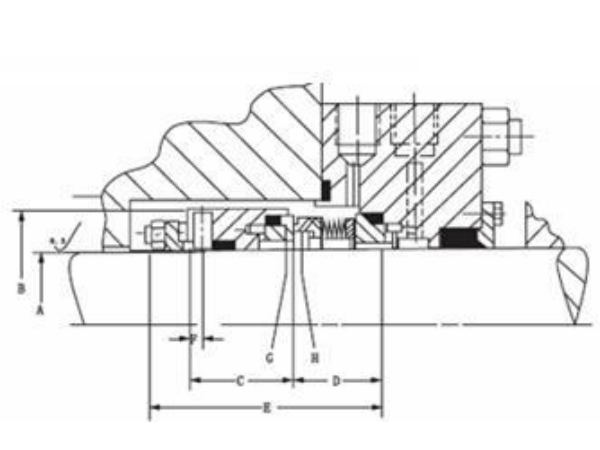

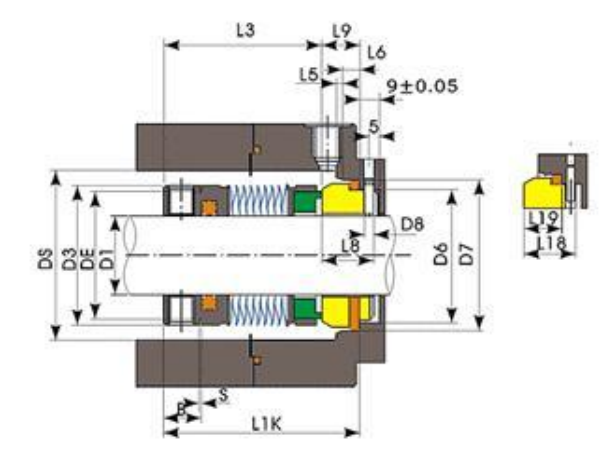

High temperature metal bellows rotary seal HW609 parameters:

HW609 High Temperature, Rotating Head Metal Bellows Shaft Seal | |

Temperature: | -75℃~ 425℃ |

Pressure: | 2.0MPa(single ply)-6.9Mpa(double plys) |

Speed: | ≤25m/s |

Equivalent John Crane Type 609 | |

Rotary Ring: | SiC/Carbon/TC |

Stationary Ring: | SiC/TC |

Secondary Seal: | Flexible Graphite |

Metal Bellows: | Heat treated AM350/Inconel 718 |

Other Parts: | Carp42 or PH17-4/316 |

High temperature rotating bellows seal HW80T parameters:

Equivalent Burgmann Type MFL85N | |

Rotary Ring: | SiC/Carbon/TC |

Stationary Ring: | SiC/TC |

Secondary Seal: | VITON/PTFE Coated VITON/PTFE |

Metal Bellows: | SUS316L/AM350/Inconel718 //Hastelloy-C/ |

Other Parts: | SUS304/SUS316//Hastelloy-C |

Applications of High temperature rotating bellows seal:

This kind of formed bellows seal is widely used in the field of oil and gas production equipment due to formed bellows seal excellent sealing effect. This type of formed bellows seal is often used when encountering toxic media or media that are volatile or radioactive, and welded metal bellows seal are extremely expensive and do not allow external leakage from the reciprocating valve stem.

About Us

"Efficiency is the eternal theme of an enterprise." Liaoning Jinding Technology uses effective means such as scientific production scheduling, new equipment purchase, and implementation of ERP systems to continuously improve the efficiency of processing, assembly and other production links, shorten the delivery time of the complete machine, and improve the company's production efficiency and production Ability greatly improved.