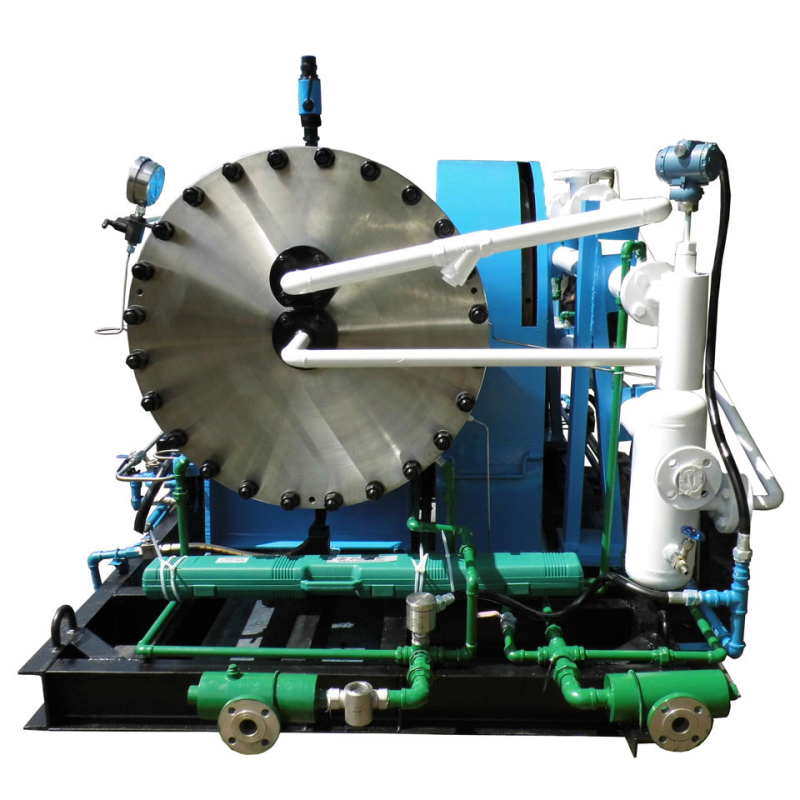

Diaphragm Compressor Bearing Wear Phenomenon and Solutions

2023-12-07 13:44The wear phenomenon of the sliding bearing (commonly known as "bearing bush") on the crankshaft of GD180 series diaphragm compressor is a very common problem. This problem is difficult to avoid. This kind of problem will occur more or less in every user unit. One of the main reasons for this failure is the failure to form an effective lubricating oil film between the crankshaft journal and the bearing bush of the GD180 series diaphragm compressor, resulting in direct friction between the crankshaft journal and the bearing bush. The cause of bearing wear in GD180 series diaphragm compressor is generally known, but it is very difficult to find out the cause.

1. Possible causes of bearing erosion and wear in GD180 series diaphragm compressor

1) The lubricating oil is of poor quality.

2) The lubricating oil pressure is low.

3) The gap between the crankshaft journal and the bearing bush is too large or too small.

4) The shape and size of the crankshaft main journal and connecting rod bore journal are out of tolerance.

5) The surface roughness of the crankshaft journal is extremely poor.

6) The flywheel dynamic balance accuracy is out of tolerance.

2. GD180 series diaphragm compressor solution to this problem

Based on the above analysis, two causes of the failure were found: lubricating oil quality issues and flywheel dynamic balance issues.

The solution to the above two problems is:

1) Replace with new lubricating oil.

2) Find the reason why the flywheel runout exceeds the standard.

If the flywheel has been dynamically balanced, you can be sure that there is nothing wrong with it. The taper sleeve and flywheel matched with it are used to ensure sufficient flywheel torque and uniform tangential force, and use the energy stored during the rotation of the flywheel to buffer the fluctuation of the rotation angle of the compressor. If the flywheel and the shaft sleeve cannot match well, it will not be able to make the rotation speed of the diaphragm compressor uniform, and it will also lose its function of compensating for load fluctuations. This also explains why the bearing bush wears to varying degrees along the circumferential direction.