Mechanical Seal

Mechanical seals are dynamic devices used to control leakage along a rotating shaft, primarily in pumps. They prevent the fluid being pumped from leaking out along the rotating shaft and are generally mounted in a gland between a pump shaft and impeller. The proper selection, installation, and operation of mechanical seals and their support systems are crucial for their performance and longevity,

The basic components of a mechanical seal include:

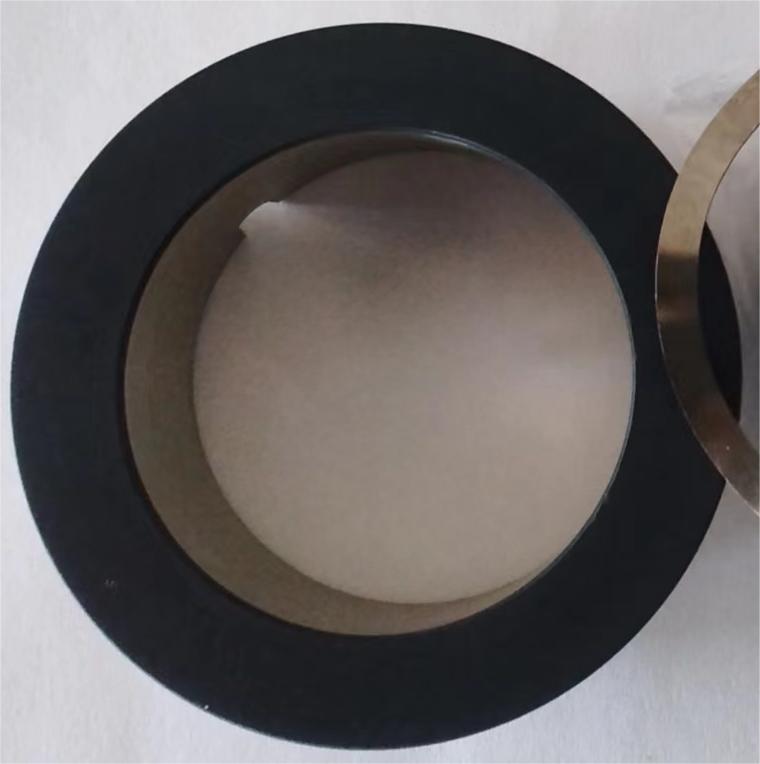

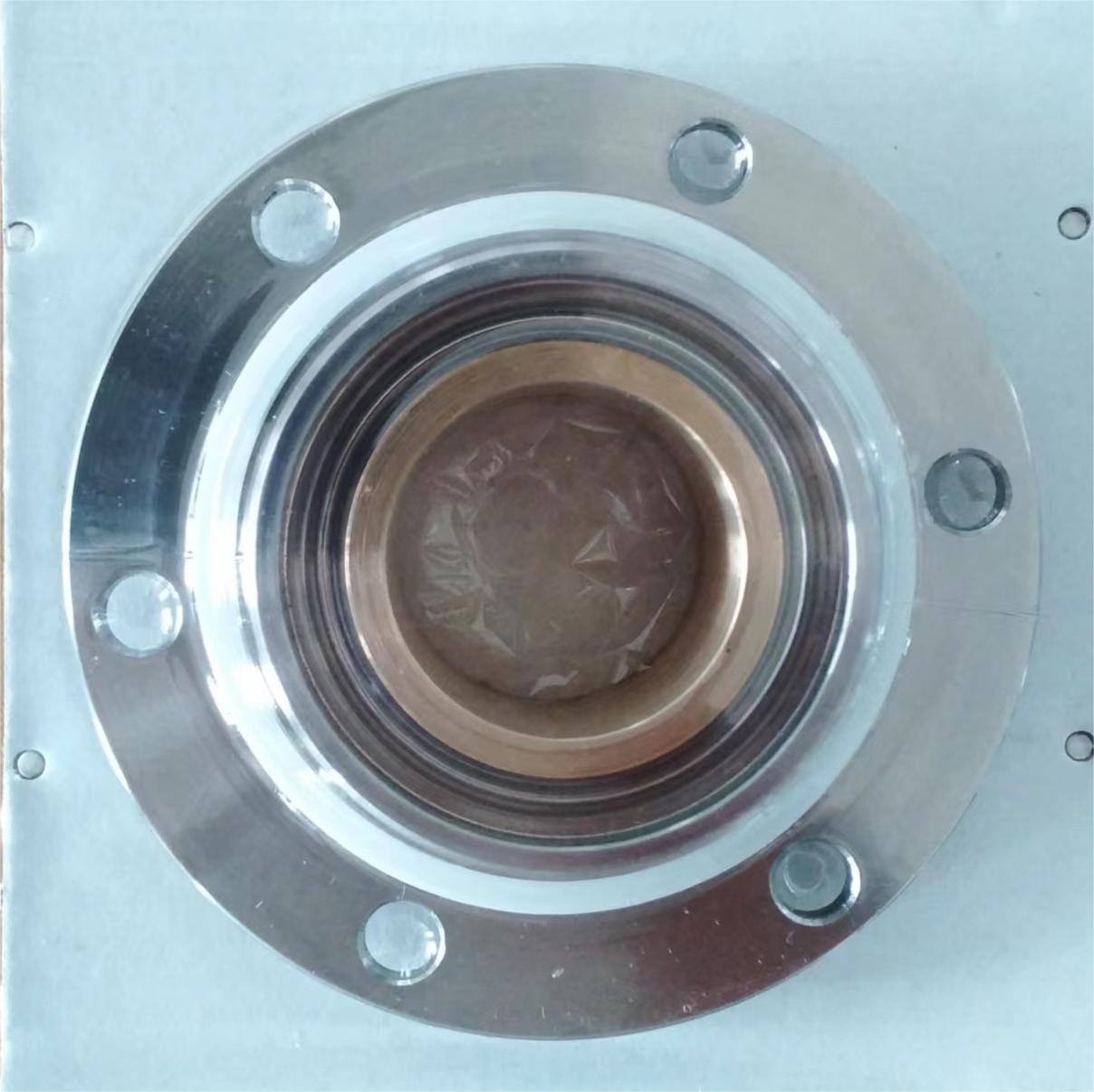

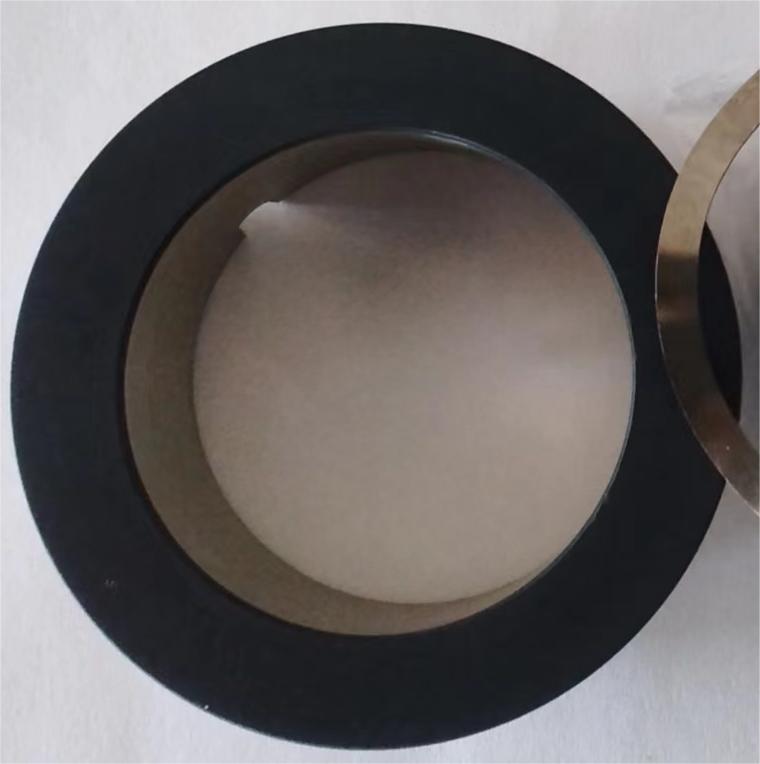

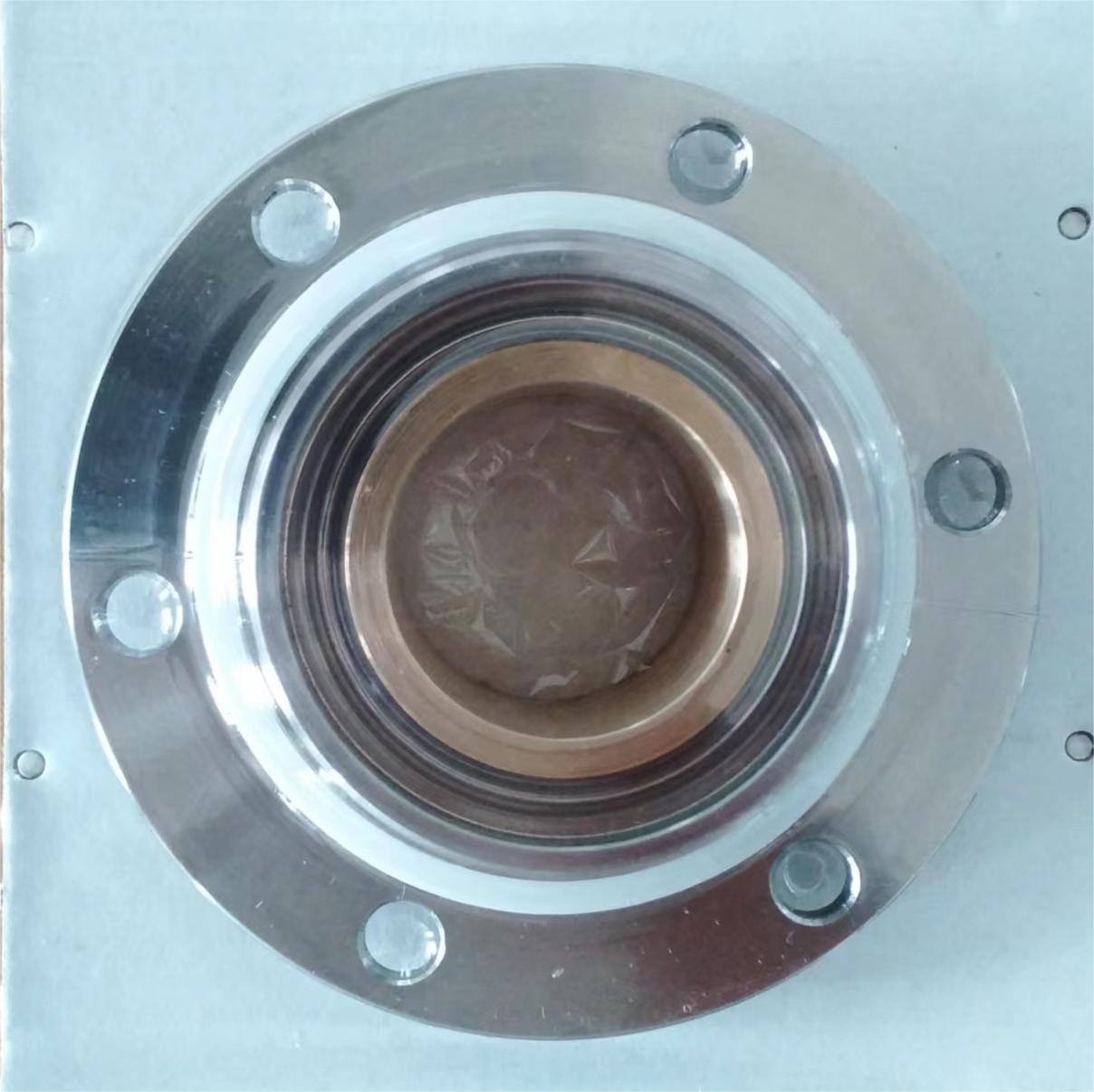

Seal Face Pair: Creates the primary sealing interface, providing rotational, dynamic sealing. Seal face pairs can be made from various materials such as carbon/graphite or hard ceramics like silicon carbide, tungsten carbide, or alumina ceramic.

Secondary Seals: Used to prevent leakage from other interfaces within the mechanical seal. These are often elastomeric materials like O-rings, gaskets, or metal/elastomer bellows.

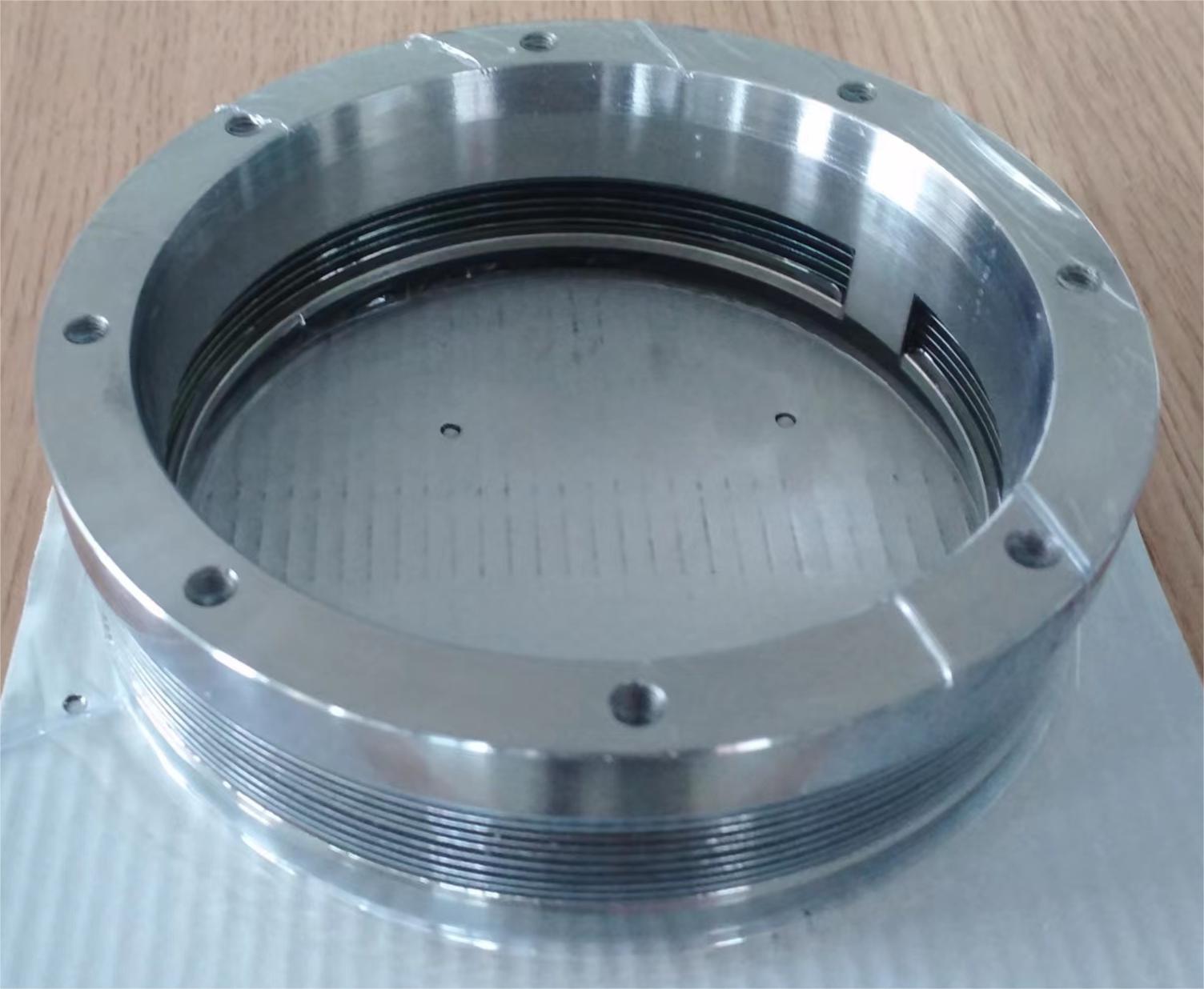

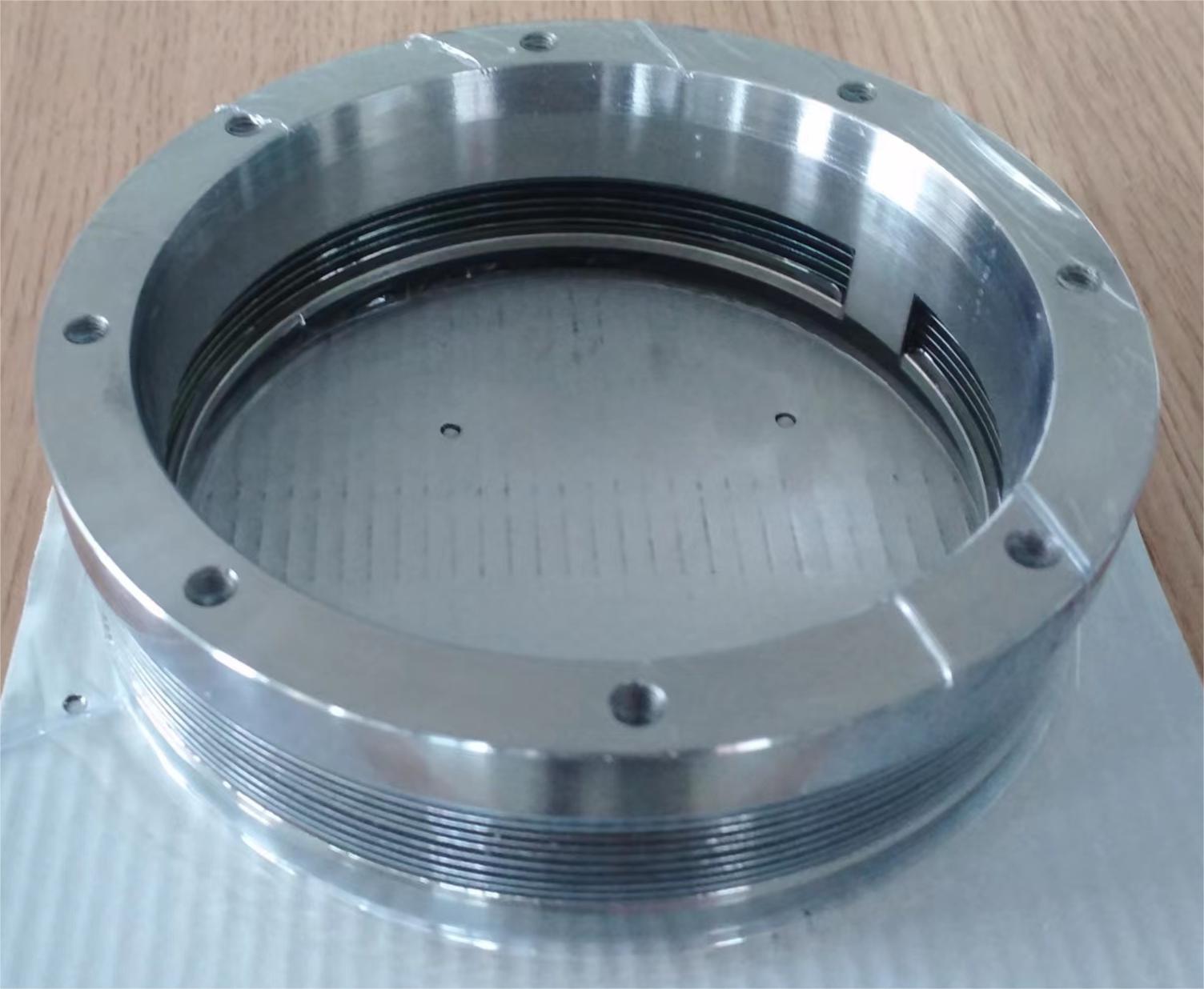

Springs & Loading Mechanisms: Maintain face contact during static, non-rotational times and dynamic tracking during operation. They can be single or multiple springs, leaf springs, wave springs, or metal/elastomer bellows.

Structural Components & Hardware: Include metal parts and hardware such as glands, sleeves, lock rings, and various pieces of hardware used in the mechanical seal.

Mechanical seals require a minuscule gap (sometimes as small as 1 micron) between the rotating and stationary faces to form a lubricating film at the interface, allowing the seal faces to slide against each other without being in full contact,

Mechanical Seal Supporting System

Mechanical seal support systems are designed to regulate the environment in which the seal operates, protecting rotating equipment from damage. They have four main functions:

Provide lubrication to seal faces

Control pressure and temperature in the seal chamber and seal

Flush the seal of contamination and/or residue build-up

Prevent system process fluid from leaking to the atmosphere.

The support systems are configured according to API 682: Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps.

In summary, mechanical seals and their supporting systems are critical components in rotating equipment, ensuring efficient operation and minimizing environmental impact. Proper design, installation, and maintenance are essential for their optimal performance.