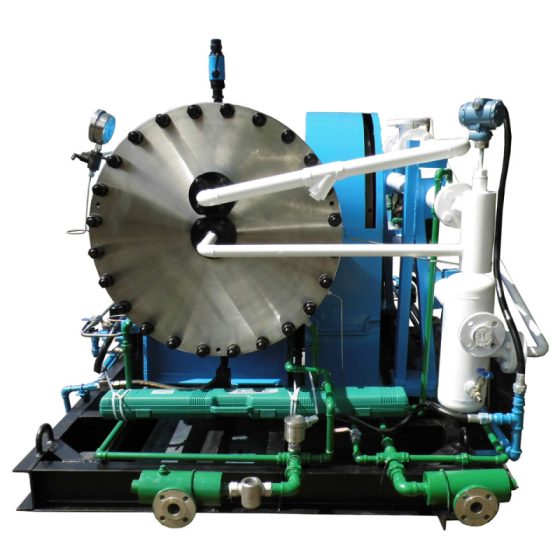

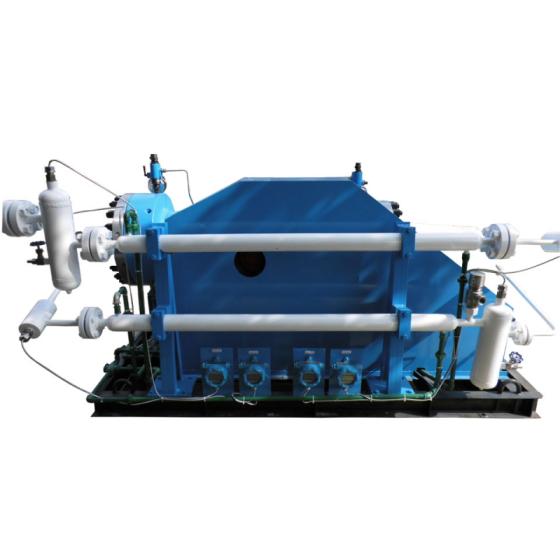

GD Series Diaphragm Compressor

1. Diaphragm compressor is a reciprocating compressor with a special structure, which has a large compression ratio and good sealing performance.

2. The gas compressed by Diaphragm compressor is not contaminated by lubricating oil and other solid impurities.

3. Diaphragm gas compressor is suitable for compressing high-purity, rare and precious, flammable, explosive, toxic and harmful, corrosive and high-pressure gases.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

Introduction of diaphragm compressor:

Diaphragm gas compressor is driven by a motor, which rotates the crankshaft through a pulley, and then through the connecting rod to make the piston in the oil cylinder move in a reciprocating linear motion, pushing the oil and causing the diaphragm to vibrate reciprocally. Under the control of the intake and exhaust valves, the diaphragm vibrates every time Once, the intake and exhaust process is completed. When the diaphragm gas compressor's diaphragm press is working, a small amount of oil in the oil cylinder leaks into the oil tank through the gap between the piston ring, cylinder wall and ring groove. In order to compensate for this part of the oil volume, so that the diaphragm can be close to the curved surface of the cylinder head at the end of the compressor stroke, and the compressed medium is discharged, the compensation oil pump injects oil into the cylinder during the suction process of the diaphragm press. The oil volume is slightly more than the leakage At the end of the compressor stroke, the excess oil flows back to the crankcase through the pressure regulating valve that controls the oil pressure.

Since the diaphragm of the Diaphragm gas compressor completely separates the cylinder from the oil cylinder, the compressed medium does not come into contact with the oil, thereby avoiding oil contamination and ensuring the purity of the compressed medium. The cylinder is composed of a cylinder head curved surface and a diaphragm. It is a closed cavity, so it has good sealing performance.

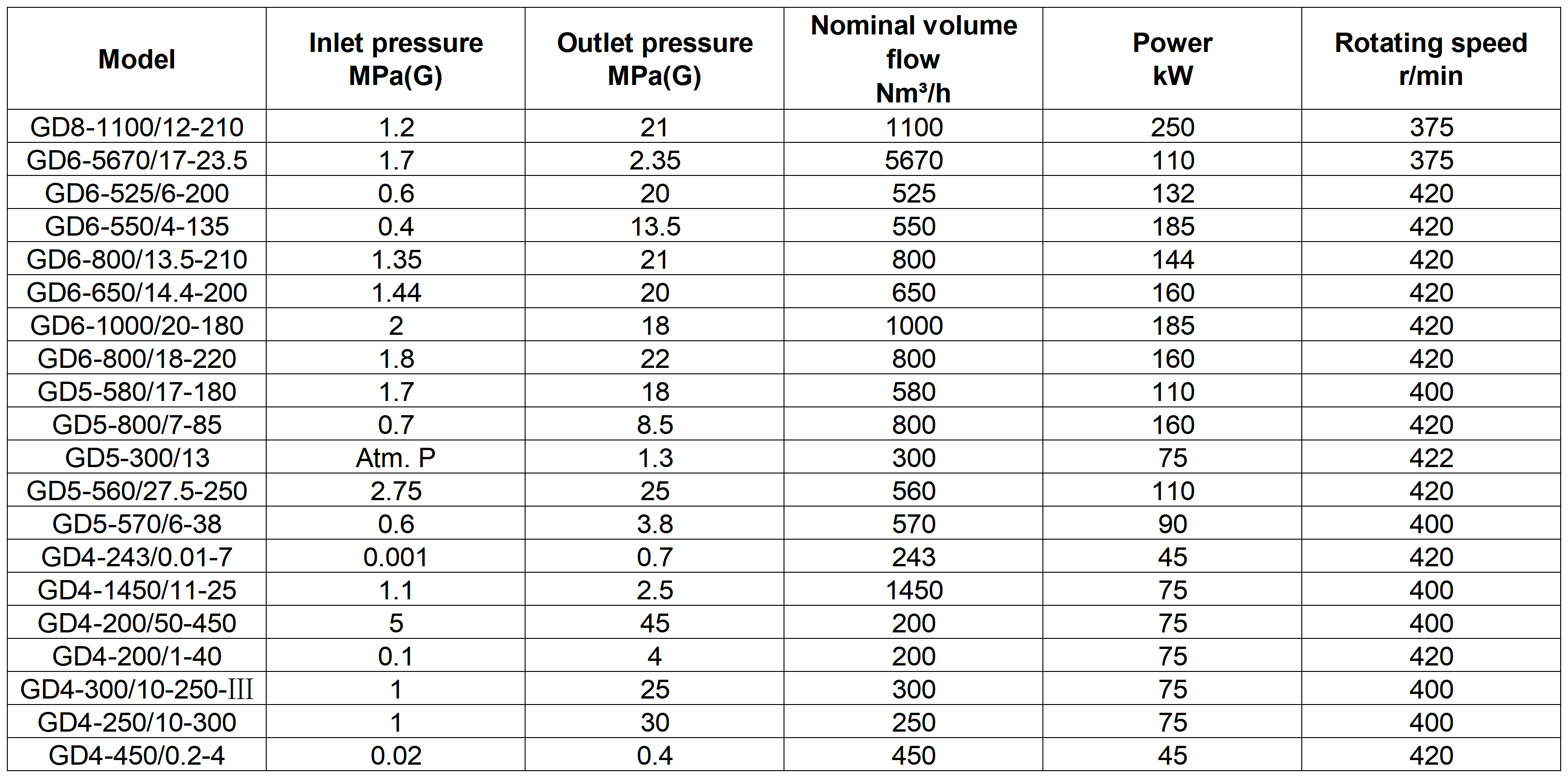

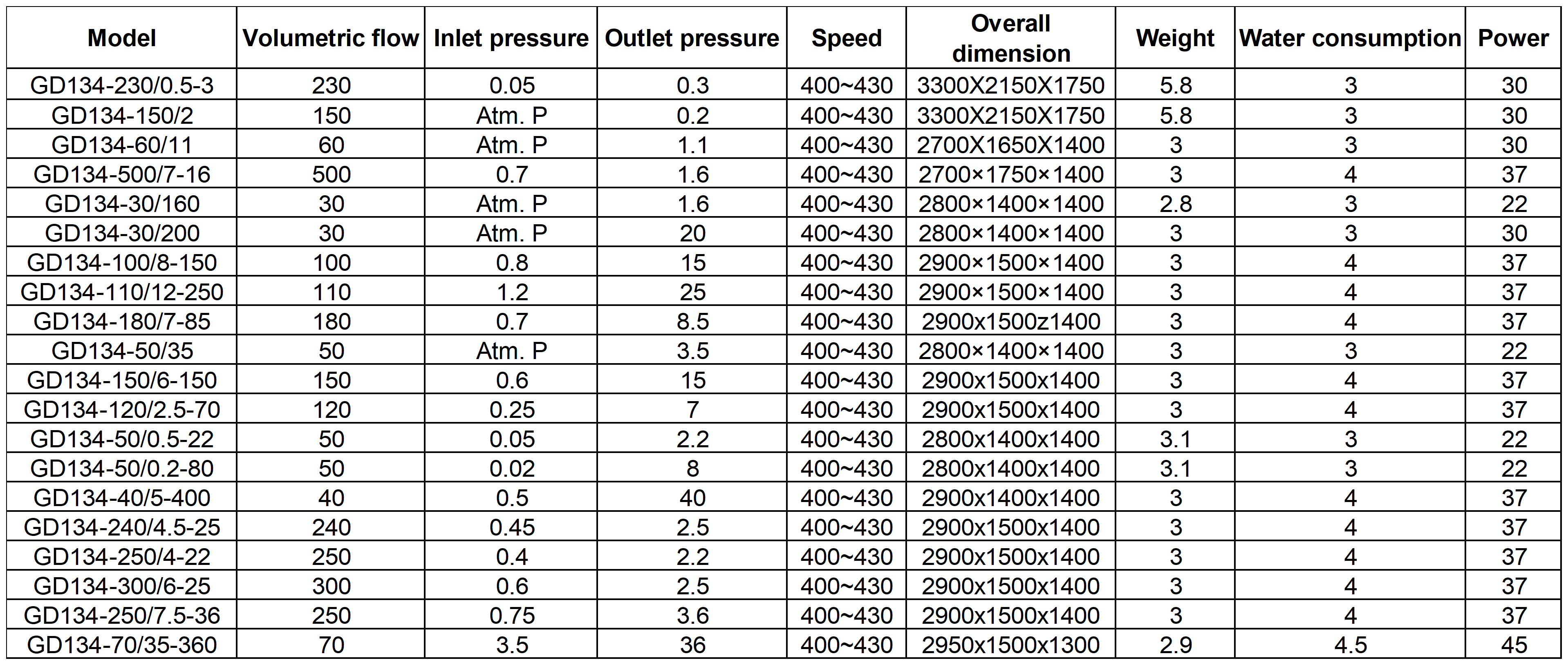

Specifications of diaphragm compressor:

Advantages of GD Series Diaphragm Compressor:

1. Type D represents the symmetrical balance type. The cylinders are on both sides of the compressor. The stress on the crankshaft is more balanced. The plane layout is more reasonable but it occupies a larger area.

2. The gas does not come into contact with any medium. Reciprocating compressor is suitable for compressing rare and high-purity gases.

3. Reciprocating compressor has good sealing, no leakage, and no oil pollution. It is the first choice for compressing toxic and harmful, flammable and explosive gases and special gases.

4. The new membrane cavity curve improves the volumetric efficiency of the Reciprocating compressor and increases the life of the wearing parts diaphragm and air valve.

5. The fully functional independent oil pump station provides stable pressure, clean quality, and fully cooled lubricating oil for compressor lubrication and oil cylinder operation.

6. The whole structure of the Reciprocating compressor is compact and reasonable, which facilitates the transportation, installation and maintenance of the equipment; it operates smoothly and reliably, with small vibration and low noise.

About us:

Liaoning Jinding Technology Development Co., Ltd. is a key enterprise in the production of Diaphragm gas compressor. It has many years of compressor production experience, strong technical force, excellent equipment, exquisite assembly and timely after-sales service. High quality products and brand-new business philosophy make the company's products accepted by users in various industries such as industrial gas, food and medicine, petrochemical industry, electronic industry, material industry, coal and scientific research. The compressed media include air, argon, hydrogen, oxygen, chlorine, neon, nitrogen, fluorine, phosphine, ethylene, acetylene, carbon dioxide, carbon monoxide, nitrous oxide, etc., which can also be customized according to the needs of customers.