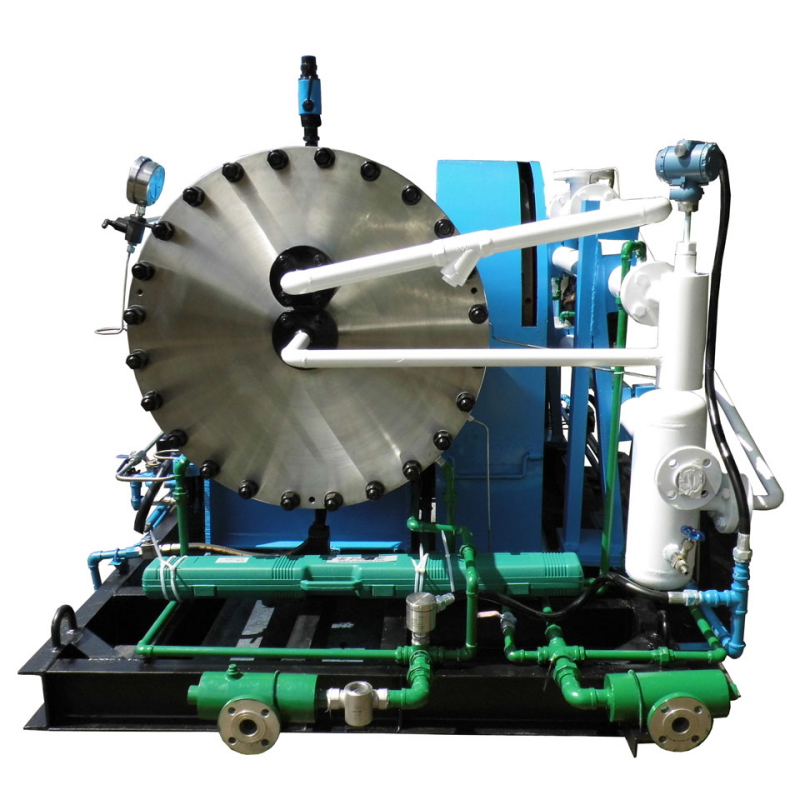

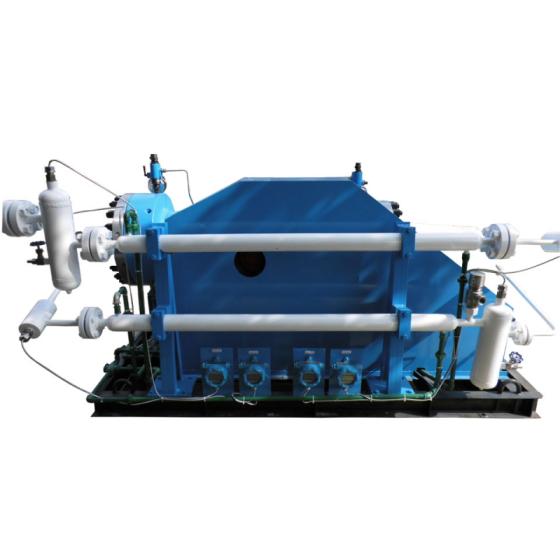

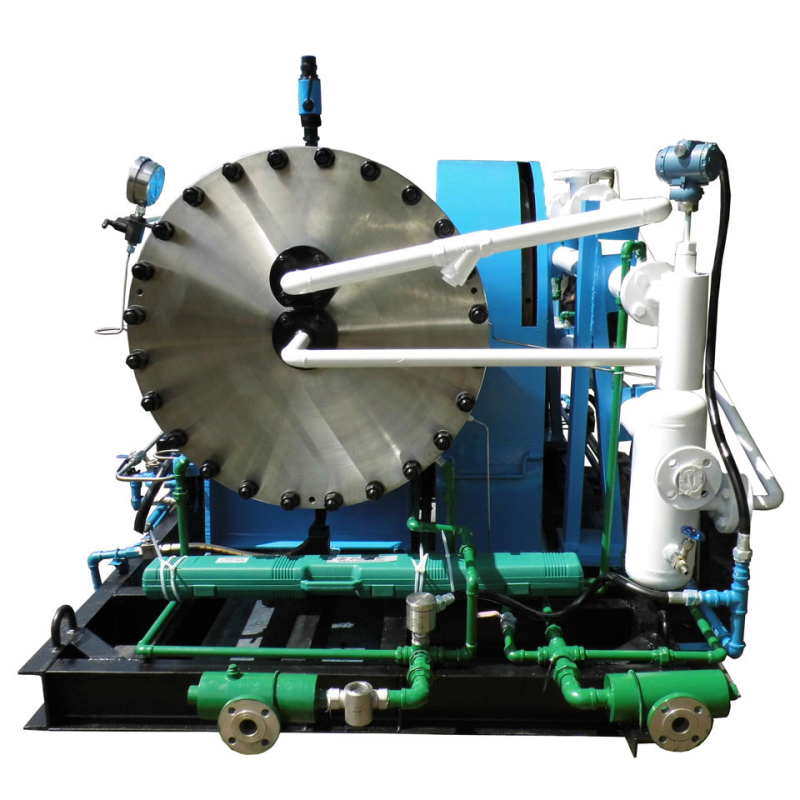

GD130 Series Diaphragm Compressor

1. The Diaphragm type compressor has a simple structure and is easy to maintain and operate.

2. Diaphragm type compressor adopts reciprocating compression method, which has relatively low energy consumption and obvious energy saving effect.

3. High pressure diaphragm compressor can achieve a higher compression ratio and compress the gas to a higher pressure.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

Introduction of GD130 Series Diaphragm Compressor:

High pressure diaphragm compressor is a positive displacement compressor. High pressure diaphragm compressor works by reducing the volume of gas to increase the pressure of the gas. They do this by using reciprocating motion to draw gas into a cylinder or chamber and compressing it using a piston or diaphragm.

Metal diaphragm compressors can operate over a wider flow and pressure range than other types of compressors, such as rotary or centrifugal. However, Metal diaphragm compressors can be noisy and produce significant vibrations during operation. Metal diaphragm compressors are ideally suited for applications where gas purity is critical and high compression ratios are required, making it a widely used compressor type in a variety of industrial applications.

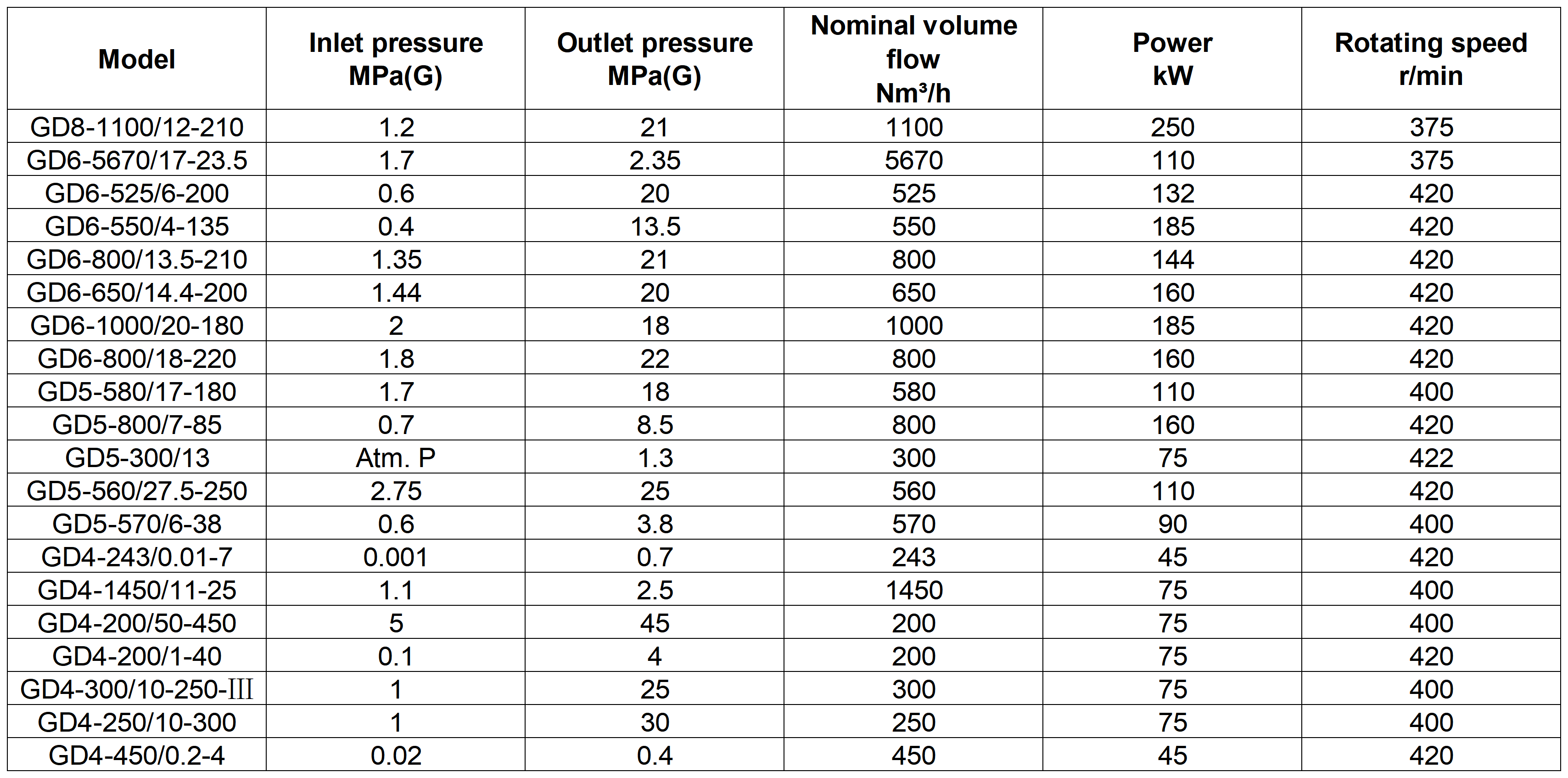

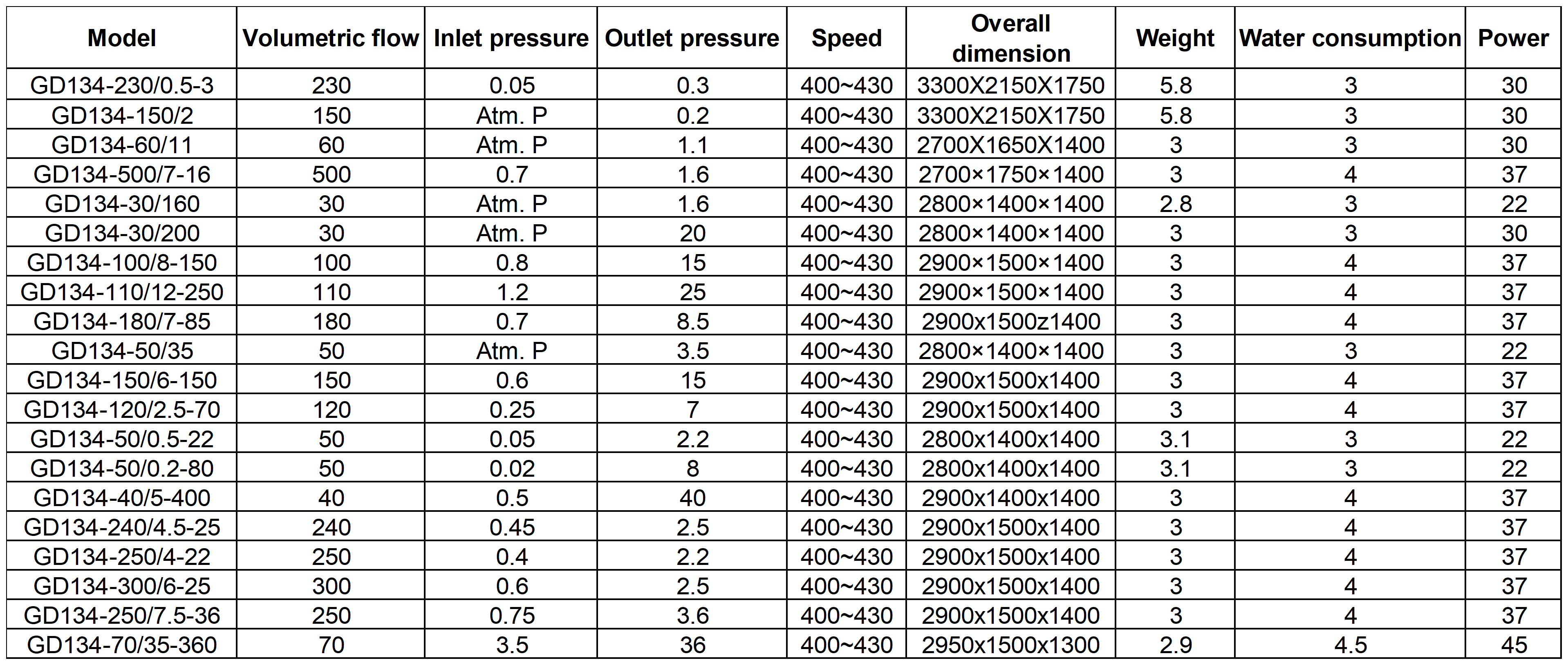

Specifications of GD130 Series Diaphragm Compressor:

Advantages of GD130 Series Diaphragm Compressor:

Helium diaphragm compressor is a special structure positive displacement compressor, which has the characteristics of large compression ratio, good sealing, no oil pollution and no leakage. This compression method has no secondary pollution and has an excellent protective effect on the compressed gas. Therefore, Metal diaphragm compressor is very suitable for compressing high-purity, rare and precious, flammable, explosive, toxic and harmful, corrosive and high-pressure gases.

The core advantage of Helium diaphragm compressor lies in its pollution-free compression characteristics, which has excellent protection effect on the compressed gas and no secondary pollution. In addition, the diaphragm chamber of the Helium diaphragm compressor can effectively prevent gas leakage. In addition, since the diaphragm chamber is completely isolated from the compression chamber and suction chamber, the part where the gas contacts the diaphragm will not be contaminated by lubricating oil, so the compressed gas does not contain oil.

We provide high-quality Diaphragm type compressors and excellent customer service, technical support and on-time delivery to help companies improve production efficiency, reduce costs and maintain high gas quality levels.

About Us:

Liaoning Jinding Technology Development Co., Ltd. was founded in 1995. After more than 20 years of innovative development, it has become a leading diaphragm type compressor manufacturing and production enterprise in China.

The company now mainly manufactures three types of compressors: diaphragm type, piston type and liquid drive type. It also specializes in the research and development and production of complete sets of acetylene production equipment. The above-mentioned products have been used in many fields such as petrochemical industry, electronic industry, food and medicine, aerospace, military industry and scientific research for many years, and have been highly recognized and widely praised by customers.

Jinding Technology looks forward to working with you to create a better future!