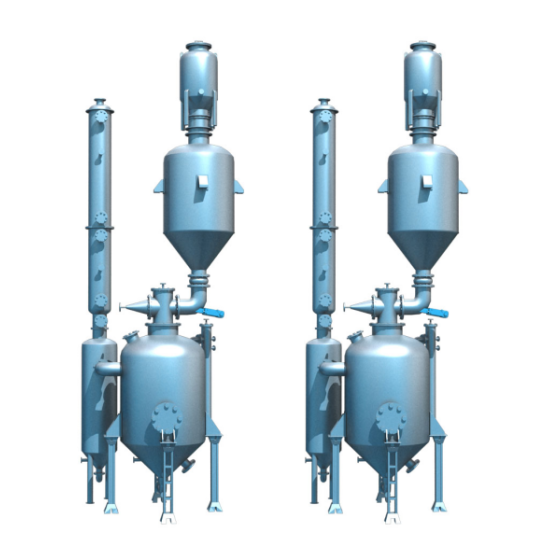

Acetylene Low Pressure Dryer

1.Our Acetylene low pressure dryer equipment is reliable, simple to operate and easy to maintain.

2.Our Acetylene low pressure dryer has strong processing capabilities.

3.Our Acetylene low pressure dryer has no acetylene loss and has high safety performance.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

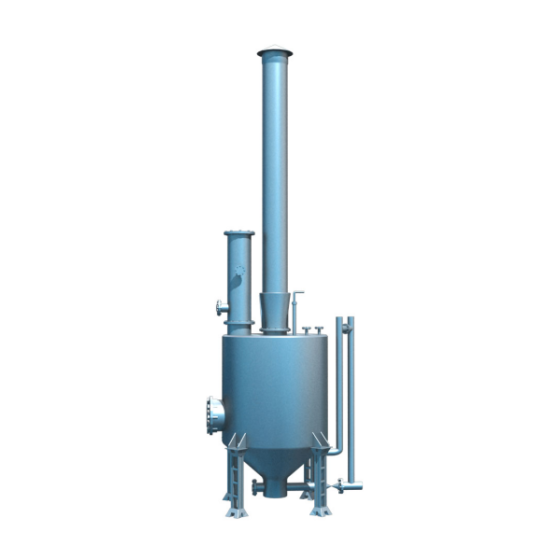

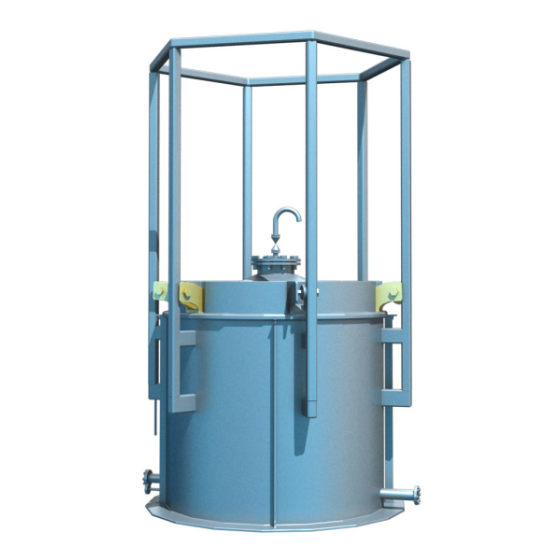

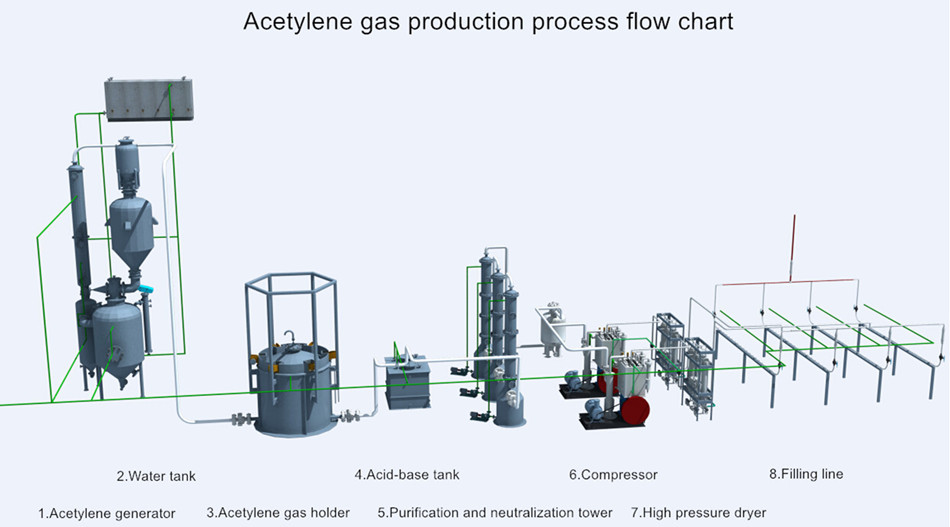

Introduction of Acetylene Low Pressure Dryer:

Acetylene low pressure dryer equipment is used to reduce the water content in acetylene gas to extend the service life of chemical purifiers, thereby increasing the output of Acetylene low pressure dryer equipment. The desiccant generally uses anhydrous calcium chloride, and its consumption index is about 0.034kg/m3 acetylene. The quantity and discharge time of Acetylene gas purifier can be adjusted according to the air flow.

Advantages of Acetylene Low Pressure Dryer:

1. Our Acetylene gas purifier uses a new type of generator, which can improve the utilization rate of calcium carbide, make the secondary reaction more complete, and save costs.

2. The drying efficiency of our Acetylene gas purifier does not change with working time.

3. Our Acetylene gas purifier has a high degree of automation, which can save labor costs.

4. Our Acetylene gas purifier uses advanced drying technology to make the molecular sieve have a longer service life.

About Us

Liaoning Jinding Technology continues to strengthen and refine the quality management and inspection standards of all employees to ensure product quality bit by bit. The production department, R&D department, and quality safety department work together to strengthen quality awareness through morning meetings, weekly meetings, and monthly meetings. During the entire process of material input, design, production, and delivery, we effectively grasp every link to ensure high quality. The product is in the hands of the customer.