Closed Oscillating Sieve Type Acetylene Gas Generator

1.The acetylene gas produced by our Closed oscillating sieve type acetylene gas generator is of high purity.

2.Our Closed oscillating sieve type acetylene gas generator is more efficient in cooling and cleaning acetylene.

3.Our Closed oscillating sieve type acetylene gas generator has a stable operating temperature and is easy to control.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

Introduction to Closed Oscillating Sieve Type Acetylene Gas Generator:

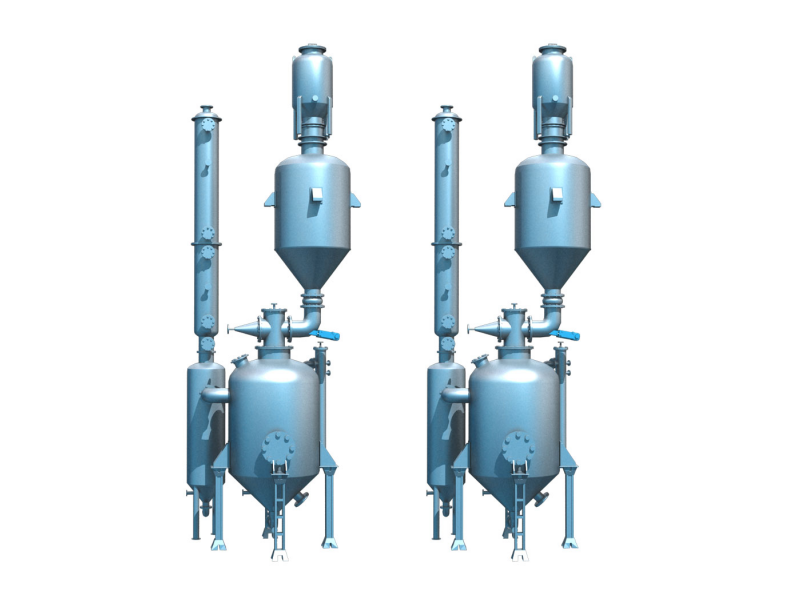

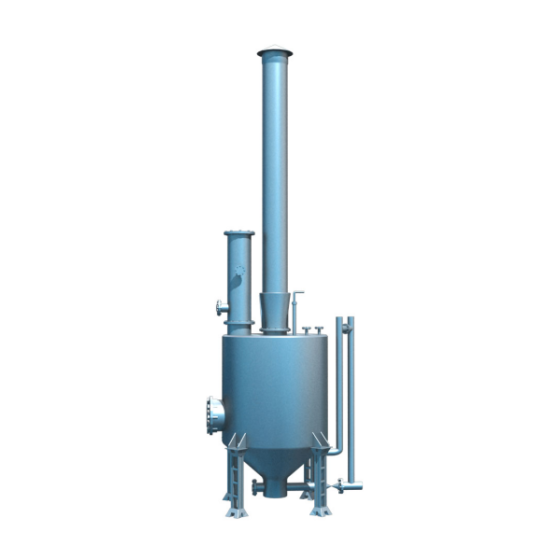

Oscillating screen acetylene generator is an advanced device designed to convert calcium carbide into acetylene gas. Oscillating screen acetylene generator is mainly composed of a main generator and a secondary generator. The calcium carbide is put into the equipment through electromagnetic vibration feeding. After the secondary reaction of the main and secondary generators, the calcium carbide is completely decomposed, thereby extracting high-purity acetylene gas.

Specifications of Closed Oscillating Sieve Type Acetylene Gas Generator:

Advantages of Closed Oscillating Sieve Type Acetylene Gas Generator:

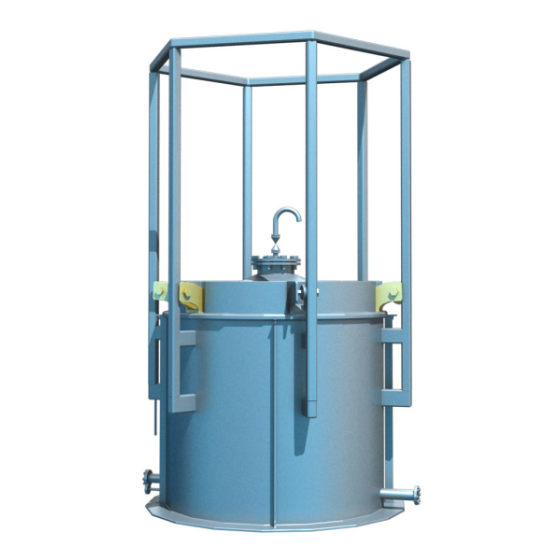

1. Our Closed oscillating sieve acetylene generator adopts fully sealed feeding and has a nitrogen purge and replacement device. Air is not easily mixed into the generator, which is safe and has a good operating environment;

2. Our Closed oscillating screen acetylene generator has a wide load adjustment range, and the productivity can generally be appropriately exceeded by 50%;

3. Our Oscillating screen acetylene generator uses thorough materials and can be used in granular shapes ranging from Φ0-80mm in size;

Features of Closed Oscillating Sieve Type Acetylene Gas Generator:

1. The calcium carbide in the Closed oscillating sieve acetylene generator is completely decomposed after the secondary reaction of the main and secondary generators, and the acetylene extraction rate is high;

2. The Closed oscillating screen acetylene generator is interlocked with the gas cabinet, making it easy to implement mechanization and automatic operation with low labor intensity;

3. The Oscillating screen acetylene generator is equipped with a secondary generator, which can improve the utilization rate of calcium carbide, save costs, and reduce the gas temperature, making the operation safer.

About Us

The company is located in a modern large-scale production and processing base in Dandong, Liaoning, China. It has advanced machinery and equipment and production lines to ensure product quality and output. The company's production center not only has high-efficiency production capabilities, but also focuses on product quality control to ensure that every product meets the company's strict standards.