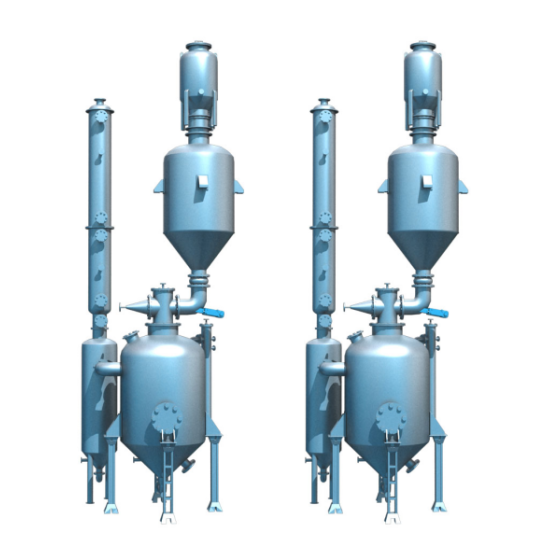

Open Type Acetylene Gas Generator

1. Our Open type acetylene gas generator has both automatic slag discharge and manual or slag discharge.

2. Our Open type acetylene gas generator acetylene gas has high purity and high calcium carbide efficiency.

3. Our Open type acetylene gas generator has a simple structure, low equipment cost and low operating cost.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

Introduction to Open Type Acetylene Gas Generator:

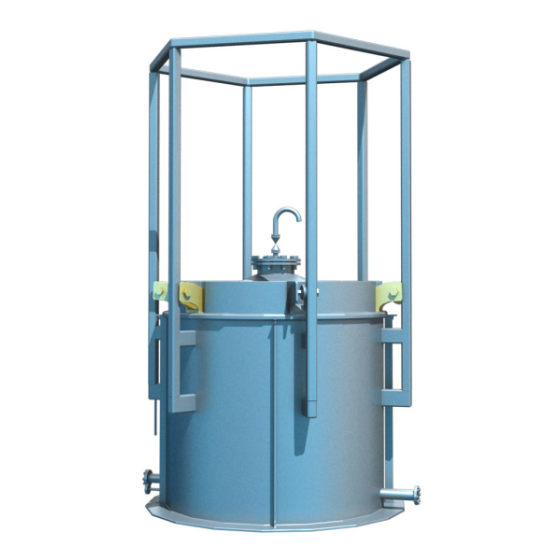

Acetylene gas generator is suitable for large pieces of calcium carbide. An explosion-proof electric hoist is used to lift the bucket. The calcium carbide reacts with water through the water surface to generate acetylene gas and calcium hydroxide. The acetylene gas from the acetylene gas generator is washed and cooled by the scrubber and then introduced into the low-pressure system. The calcium hydroxide is deposited at the bottom of the acetylene generator cone and then discharged. The gas generation capacity of Open acetylene generator is between 80~300m3/h.

Specifications of Open Type Acetylene Gas Generator:

Advantages of Open Type Acetylene Gas Generator:

1. The raw material calcium carbide for the open acetylene generator has a wide particle size range. The most suitable calcium carbide particle size is 200-50mm, which eliminates the need for crushing equipment and dust removal equipment.

2. The open acetylene generator, washing tower and safety water seal are integrated into one, which can ensure the safe operation of the open acetylene generator.

3. When the open acetylene generator is turned on, a nitrogen replacement is performed. Our acetylene generator uses less nitrogen and wastes less acetylene gas.

Applications of Open Type Acetylene Gas Generator:

Open acetylene generator is suitable for large pieces of calcium carbide. The calcium carbide with a particle size of less than 200mm is loaded into a bucket, and an explosion-proof electric hoist is used to lift the bucket, and then the material is fed manually or by a belt conveyor. Calcium carbide is added into the barrel from the upper part of the feeding barrel and enters the inside of the acetylene generator through the water surface. It is evenly distributed on the grid plate through the distributor, where it reacts with water to generate acetylene gas and calcium hydroxide. In the acetylene generator, due to the water sealing effect of the charging barrel and overflow pipe, the acetylene gas can only be washed and cooled by the scrubber with spray water and then introduced into the low-pressure system.

Why choose our company

Our acetylene generators are of excellent quality. We will continue to adhere to the concept of "gold products are manufactured for a lifetime" and work with our customers to create a better future with excellent product quality, all-round services and good reputation.