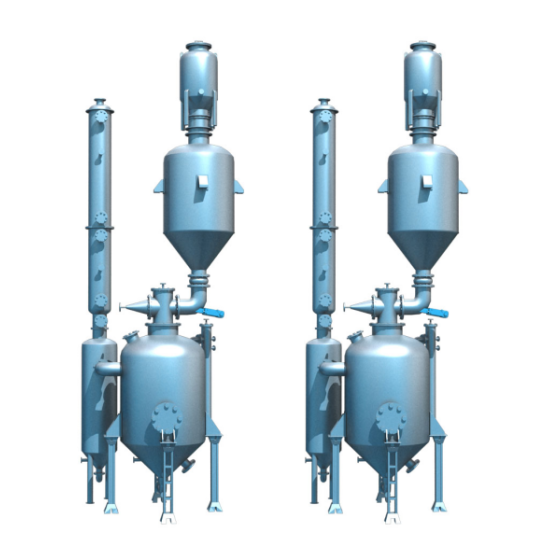

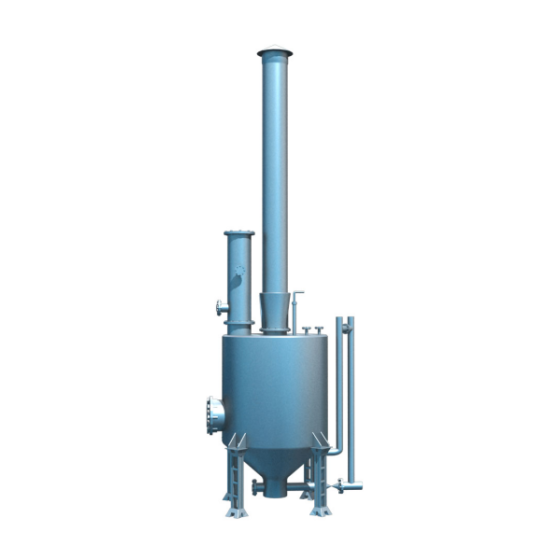

Acetylene Molecular Sieve High Pressure Dryer

1. Our Acetylene Molecular Sieve High Pressure Dryer has efficient processing capabilities.

2. Our Acetylene Molecular Sieve High Pressure Dryer can save filler costs.

3. Our Acetylene Molecular Sieve High Pressure Dryer has high safety.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

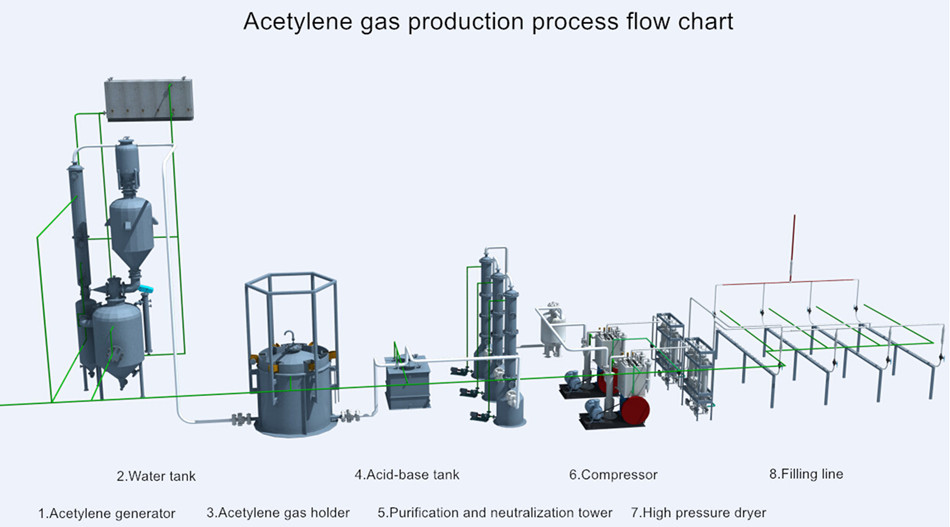

Introduction to Acetylene Molecular Sieve High Pressure Dryer:

Acetylene molecular sieve high pressure drying equipment is a type of equipment used for high-pressure gas drying, using molecular sieve technology. Acetylene molecular sieve high pressure drying equipment has the advantages of high efficiency, speed, safety and energy saving, and is widely used in petrochemical, electronics, food, medicine and other industries.

The principle of Acetylene Molecular Sieve High Pressure Dryer:

Acetylene molecular sieve dryer uses the adsorption characteristics of molecular sieves to adsorb moisture on the molecular sieve, and then blows the moisture away from the molecular sieve through high-pressure air to obtain dry gas. Acetylene molecular sieve dryer can operate under high pressure, so it is suitable for occasions requiring high pressure drying.

Advantages of Acetylene Molecular Sieve High Pressure Dryer:

1. Acetylene molecular sieve dryer can quickly absorb moisture and blow away moisture quickly to improve drying efficiency.

2. Fully automatic molecular sieve acetylene dryer adopts high-pressure drying technology, which can reduce the occurrence of safety accidents such as explosions.

3. Fully automatic molecular sieve acetylene dryer adopts efficient adsorbent and optimized design, which can reduce energy consumption.

4. Fully automatic molecular sieve acetylene dryer can reduce exhaust emissions and is environmentally friendly.

About Us

"Efficiency is the eternal theme of an enterprise." Liaoning Jinding Technology uses effective means such as scientific production scheduling, new equipment purchase, and implementation of ERP systems to continuously improve the efficiency of processing, assembly and other production links, shorten the delivery time of the complete machine, and improve the company's production efficiency and production Ability greatly improved.