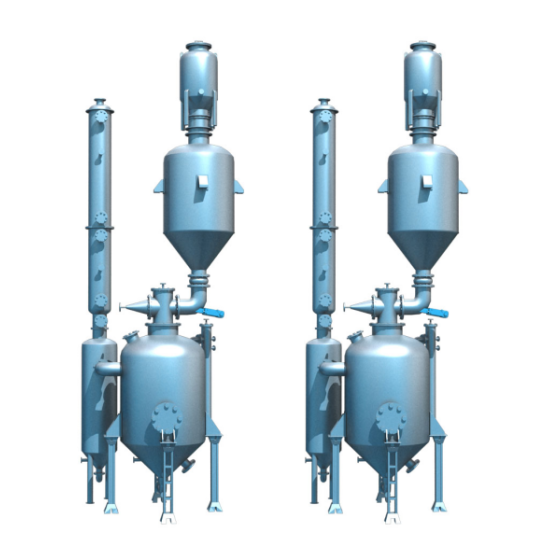

Spray Purification And Neutralization System

1. Our spray purification and neutralization system has a compact structure and a small footprint;

2. Our spray purification and neutralization system is simple to operate and easy to maintain;

3. Our spray purification and neutralization system has low investment cost.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

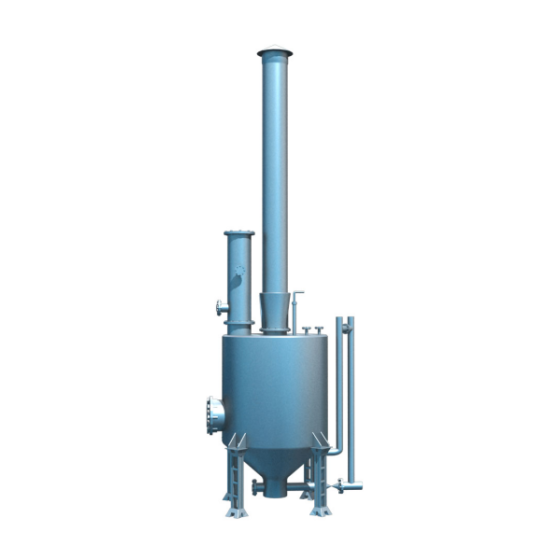

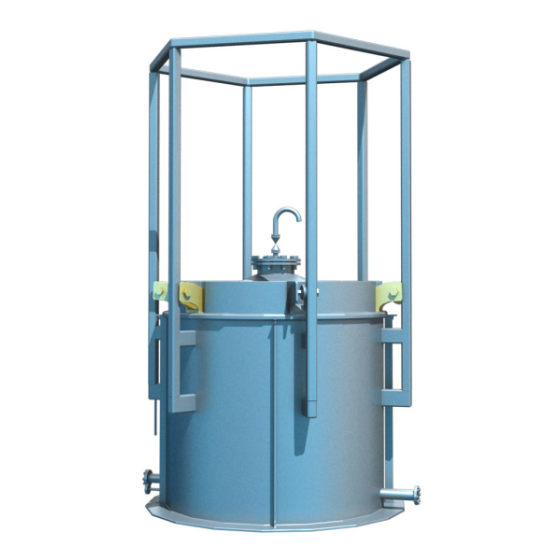

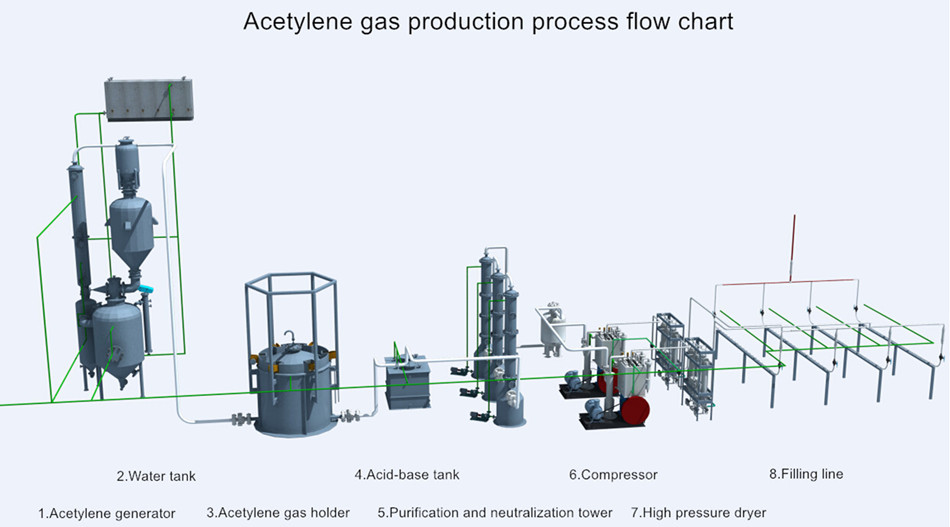

Spray purification and neutralization system neutralization process:

In the spray purification neutralization system, the generated crude acetylene gas first enters the first purification tower to contact with dilute sodium hypochlorite, and then enters the second purification tower to contact with concentrated sodium hypochlorite to remove phosphine, hydrogen sulfide and other impurities in the acetylene gas, and then the acetylene gas After entering the neutralization tower, sodium hydroxide solution is used to remove the acid mist. The qualified acetylene gas exits from the top of the neutralization tower and is sent to the gas cabinet or compression process. Each tower uses a circulation pump for circulation operation. After the sodium hypochlorite solution is prepared, pump it into the second clear tower for use, and the dilute sodium hypochlorite with reduced concentration is pumped into the first clear tower as a detergent.

Advantages of Spray purification neutralization system:

1. Due to the uniqueness of the pharmaceutical intermediates industry, the purification liquid is continuously and automatically replenished, and the residual liquid is automatically discharged, which overcomes the defect of unstable purification quality of the original acetylene gas spray purification tower, and can be adjusted according to the size of the acetylene gas treatment gas. The amount of purification liquid added keeps the Spray purification neutralization system in the most effective operating state;

2. The added sodium hypochlorite is circulated in the pump and then sent to the top of the acetylene gas spray purification tower. The effective chlorine content will not exceed the standard, making safety more secure;

Spray purification and neutralization system features:

1. The acetylene gas spray purification tower adopts sodium hypochlorite purification method and has good corrosion resistance. Features of long service life.

2. Our acetylene gas spray neutralization tower is designed and manufactured in strict accordance with national purification equipment standards.

3. The 10% silver nitrate test paper will not discolor, reaching the national standard after acetylene gas purification.

4. Our acetylene gas spray neutralization tower has a large gas processing capacity and can work continuously.

5. Our acetylene gas spray neutralization tower is a fully low-pressure process. It does not contain acid and alkali components when it leaves the purification tower and does not affect the life of the compressor.

About Us

Liaoning Jinding Technology Development Co., Ltd. has always adhered to the core value concept of "gold manufacturing, Dingnuo life". We focus on bringing excellent quality and comprehensive solutions to every customer. In order to achieve this lofty goal, the company has formed an elite team with rich industry experience and excellent professional skills. Whether it is product R&D, design, manufacturing or after-sales maintenance, this team can provide comprehensive and efficient services and support to meet the various needs of customers.