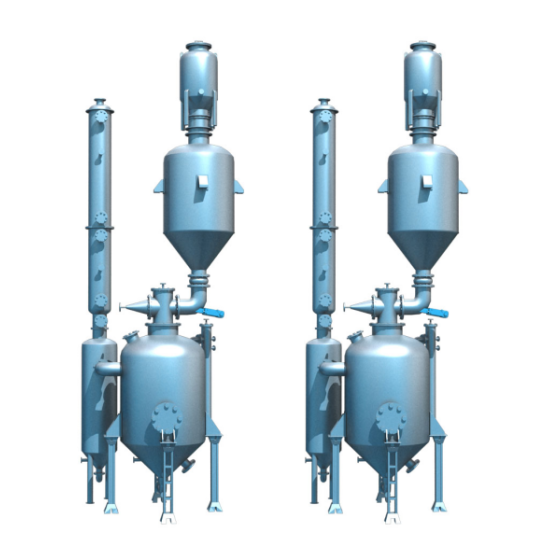

Sulfuric Acid Bubbling Purification And Neutralization System

1. Our Sulfuric acid bubbling purification and neutralization system has good gas purification effect.

2. Our Sulfuric acid bubbling purification and neutralization system handles large gas volumes.

3. Our Sulfuric acid bubbling purification and neutralization system purification liquid replacement cycle is long.

- Dandong City, Liaoning Province

- 2 months

- 18 units/month

- Information

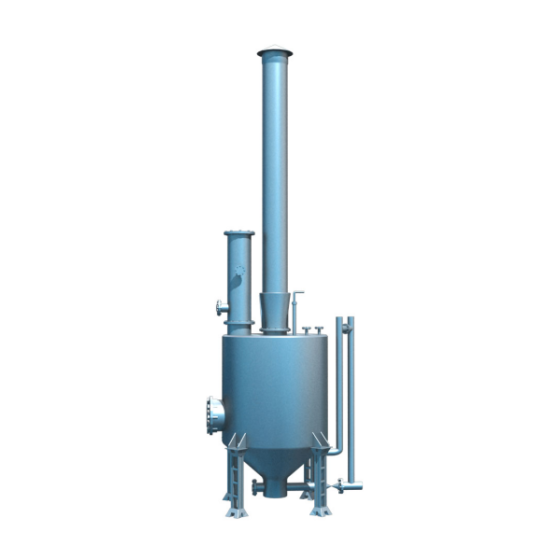

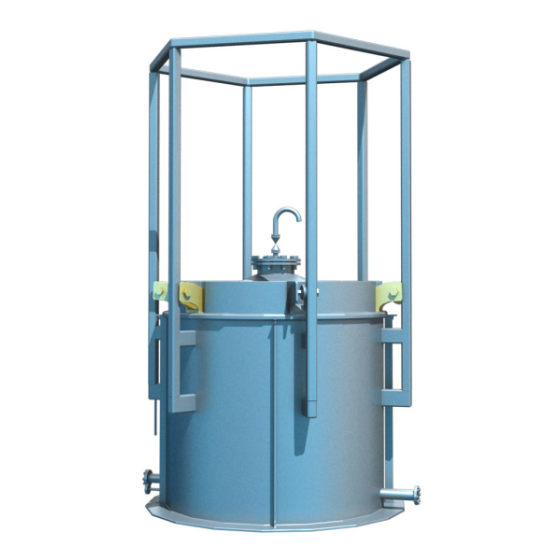

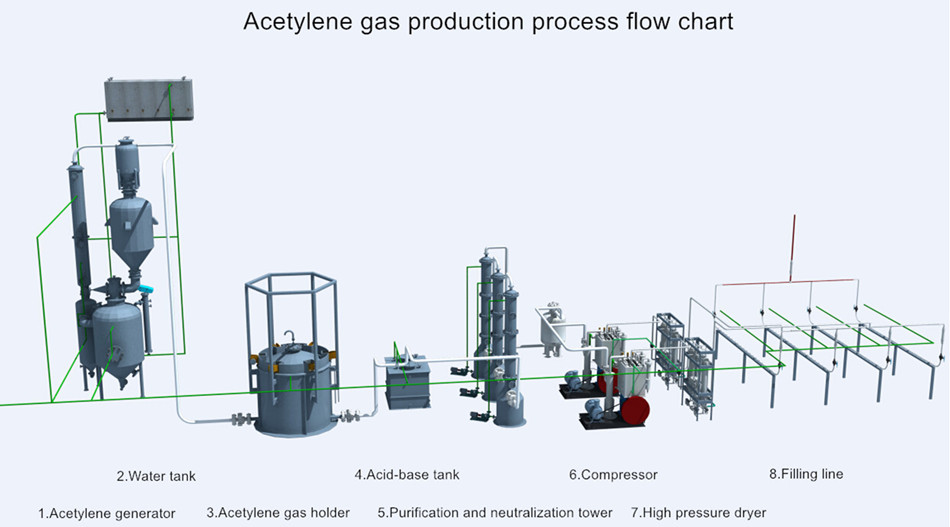

Introduction to Sulfuric acid bubbling purification and neutralization system:

In the sulfuric acid bubbling purification and neutralization system, the acetylene gas enters the first purification tower after cooling and other treatments, and uses dilute sulfuric acid (70%-80%) to dry and remove impurities. Then it enters the second purification tower (main Neutralization tower、Purification tower) of the low pressure acetylene gas generator, and uses concentrated sulfuric acid (85-97%) to reduce the content of impurities such as phosphine. Then it enters the third tower of the low pressure acetylene gas generator, and uses neutralizing liquid (concentration 4%-8%) to turn the acid in acetylene into a soluble salt and remove it. Sulfuric acid and sodium hydroxide solutions driven by corrosion-resistant pumps are used to inject acetylene gas. Finally, it enters the compression system through the filter of the low pressure acetylene gas generator to ensure the cleanliness of the compressor inlet of the acetylene gas plant. The purification tower (Neutralization tower)of acetylene gas plant is filled with polypropylene saddle-shaped corrugated packing to increase the gas-liquid contact area.

Advantages of acetylene gas purification and neutralization system:

1. The sulfuric acid bubbling purification and neutralization system is an efficient acetylene gas plant. Its gas purification effect is very good, and it can effectively remove harmful substances in the gas, making the treated gas purer.

2. The acetylene gas plant can handle a large amount of gas and can meet the needs of large-scale industrial production.

3. The purification liquid replacement cycle of acetylene gas plant is very long, and it can operate stably for a long time, which reduces the trouble of frequent replacement of purification liquid and saves a lot of manpower and material resources for the factory.

Our acetylene gas purification and neutralization system

In terms of production and manufacturing, the company focuses on excellence and strictly controls every production link. From the procurement of raw materials to the delivery of finished products, every step is strictly controlled to ensure that the quality and performance of the products meet the highest standards. At the same time, the company's production team also actively explores new production processes and technologies to improve production efficiency and quality, and provide customers with more high-quality products.